By: Ashraf Mall

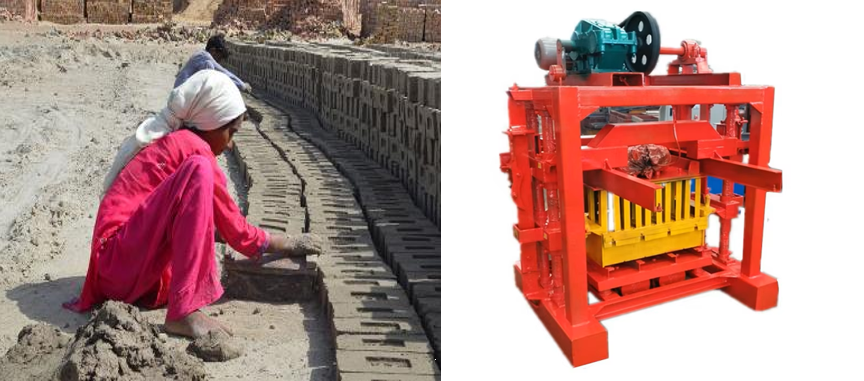

Pakistan’s construction industry is at a decisive moment, where the shift from traditional handmade bricks to modern, machine-made alternatives could shape not only the quality of national infrastructure but also the future of millions trapped in bonded labour. The conversation around brick-making technology has expanded beyond engineering performance, touching on long-standing social and economic injustices that continue to affect entire families, particularly women and children, across the country.

In recent years, evidence from kiln owners, builders, masons, and civil engineers has pointed toward the advantages of machine-made bricks, especially those produced using sand lubrication. These bricks demonstrate greater strength, consistency, and durability compared to handmade ones, while also offering a pathway to transform labour practices in the sector. A notable example of this innovation comes from Faisalabad, where Muhammad Umar of Umar Engineering has developed a sand-lubricated brick machine that replaces diesel oil with sand. Umar explains that sand provides a clean release from the mold and creates a natural surface texture that forms a stronger bond with cement.

Diesel-lubricated bricks, by contrast, often carry an oily film that weakens mortar adhesion and disrupts water absorption. Kiln owners in Narowal, Chiniot, and Faisalabad report that sand-lubricated machine-made bricks deliver improved strength, better bonding, and more predictable water absorption, and builders working with them confirm that their performance matches or exceeds that of high-quality handmade bricks.

Construction companies are also recognizing the benefits. Prime Perk Construction’s CEO Mohammad Irfan notes that machine-made sand-lubricated bricks retain their structural integrity during the rainy season and create a stronger, more reliable mortar bond.

Masons working directly with these bricks echo the industry’s confidence. Manzoor, a mason from Chiniot, says, “It feels like working with the best handmade bricks. Their strength is amazing, and we recommend them for house foundations.” Another mason, Mohammad Tariq, who has laid more than 600,000 sand-lubricated bricks, adds, “There are no issues with bricks falling or mortar failing. These bricks are reliable and widely used even in government construction projects.”

Civil engineering observations support these practical experiences. Engineer Muhammad Umar confirms that diesel residue negatively affects mortar adhesion and water absorption, while sand-lubricated machine-made bricks consistently show better results in both laboratory and field settings. He recommends that engineering institutions such as UET Lahore take the lead in documenting and standardizing these findings for wider industry adoption.

The implications of this technological shift reach far beyond construction quality. Handmade brick molding remains one of the largest contributors to bonded labour in Pakistan, where entire families remain trapped in cycles of debt with little chance of escape. Machine-made bricks require significantly less manual labour, creating an opening to reduce dependence on bonded workers and offering opportunities for rehabilitation.

Organizations such as the Pakistan Partnership Initiative (PPI) and Families Set Free (FSF) are at the forefront of promoting machine-made brick technology while simultaneously supporting families who leave the kilns. Their efforts include providing access to education, vocational training, and leadership development for children and youth who have long been excluded from formal learning and economic opportunity.

This moment presents Pakistan with a chance to link technological advancement with social justice. The growing evidence points toward machine-made, sand-lubricated bricks as a solution that strengthens construction, reduces cement usage and overall costs, and helps free families from exploitative labour systems. By modernizing its brick industry, Pakistan can encourage a more transparent, efficient, and humanitarian model of development—one that builds not only stronger structures but also a stronger society. The choice to transition from handmade to machine-made bricks could become one of the most significant economic and social transformations of the decade, laying the groundwork for a fairer and more prosperous future.